While one would expect some nuclear testing to take place at America’s notable liquid metal testing facility, we don’t expect them to dive into the gaming world. To be fair though, the nuclear workforce here wasn’t so much playing video games as they were conducting experiments using gaming tech.

It is claimed that engineers at the Argonne National Laboratory used “extended reality tools” to conduct recent tests and to train a nuclear workforce.

Many nuclear reactors in the United States were built several decades ago by a nuclear workforce that has since retired or will be doing so relatively soon. In fact, life since then has not only changed but has become far more automated.

Thus, many factories and labor jobs alone have started to use a lighter staff. Mostly because machines can do the job of 10 to 20 men. Therefore, the nuclear workforce changed dramatically over time.

The original reactors used paper checklists and literal blueprints to make those very reactors. Most never needed to leave their employers, and often worked locally. Yet as times have changed, we have done away with the need for many uses of paper and employment has changed massively.

Times Are A’Changin

Compared to past technicians in a nuclear workforce or any workforce really, those of today have different needs and expectations at their workplace. Subject matter experts & engineers also need to have different skills due to the changes in technology. Most of the workforce today is part of the “computer generation.”

As in, those born as computers became prominent across many industries (roughly 1990s and beyond). On top of that, employers and even where one lives can change far more than they did during the time our grandparents and even parents were a major part of the workforce.

In fact, today remote work is all the rage as is the aspect of employers. As well as offering work at roughly 39 hours a week…one hour shy of full-time. Of course, full-time workers get things like medical coverage, and employers would rather avoid that if possible.

This generation is also very experienced with video games, and digital information technology. Plus, we have personal devices such as cell phones nearby at all times.

The nuclear power industry must change and find a way to keep up with the times. Mostly because, quite frankly, a lot could be done better here. That has resulted in labs like Argonne deciding to test new ways to make things work.

The Nuclear Renaissance

Nuclear power has been proven to be relatively clean compared to things like coal and other traditional ways we get power. As a result, the potential to do even more with nuclear energy is immense. Yet in order to do this, you need to bring in the right people.

The problem is, once you bring them in, they need to be trained. How do we train those people? Argonne feels that is where the gaming industry comes in. Whether is maintaining current nuclear plants or building new ones, you need to have people that are capable of doing the job.

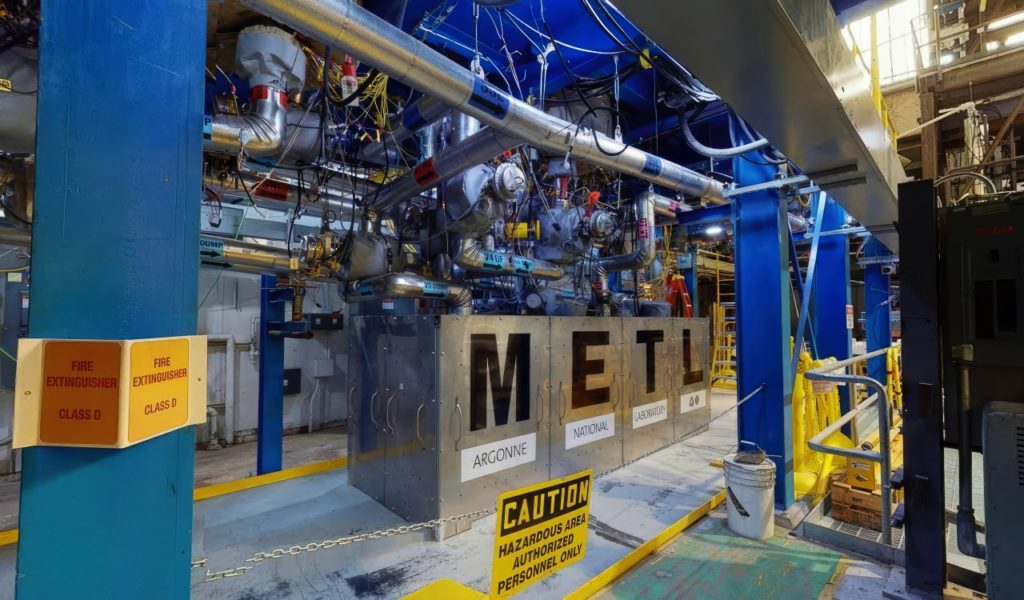

This is why Argonne has been experimenting with the use of Deploying Extended Reality (XR) for Digital Operations & Maintenance at the Mechanisms Engineering Test Loop (METL). They decided to use personal devices and video game technology could be best.

Especially since many are familiar with them and could use what they learn in the real world. That’s helpful for your future nuclear workforce.

Principal Mechanical Engineer & METL Operations Manager, Derek Kultgen, said of this move:

“As everything transitions to digital, there is an opportunity to use extended reality to break down the silos where useful data resides and bring data to the people who need it.”

The Need For New Nuclear Professionals

The Nuclear Energy Institute recently claimed that a single nuclear power plant employs between 500 to 800 workers. All of which come with a wide range of special skills. They employ health physicists, financial managers, carpenters, electricians, welders, and obviously nuclear engineers.

The nuclear field needs people to work for these plants and facilities. Obviously, that means they want to develop those who choose to take part. They not only need former military members but also those from four-year universities and even community colleges.

Kultgen believes that an engaging, digitally enhanced workplace can be a big help with this. At Argonne, where he works, the METL facility works with small to medium-sized components that are used for advanced, sodium-cooled nuclear reactors.

Heck, this facility literally holds 750 gallons of reactor-grade sodium that can be heated to upwards of 1200 degrees Fahrenheit or over 650 degrees Celsius. Plus, it is equipped with more than 1,000 sensors that help to collect diagnostic data.

Of course, even when experiments are not ongoing at METL, the facility provides a lot of value. As they are known for being great at training people and collecting operations data.

Kultzen went on to claim:

“As everything transitions to digital, there is an opportunity for the nuclear industry to use extended reality to break down the silos where useful data resides and bring data to the people who need it. These digital silos include Computer-Aided Design (CAD) information, operating and maintenance procedures, real data coming off the equipment, manufacturer data, data on spare parts, historical data of how this equipment has operated, and more. This breaking down of information barriers between occupations means meaningful work across the board, and that may result in a future workforce that is trained, competent, and content enough to stay for a while.”

Training For Tomorrow’s Workers

Kultgen and his colleagues at METL began to experiment with assisted, augmented, virtual, and even mixed reality. Most of it was off-the-shelf hardware and software that would be familiar to many gamers.

This included stuff like headsets, tablets with LiDAR, high-fidelity visualization software, hardware with advanced optics, short-range wireless tech, & voice-activated software.

With help from a computational designer, the team created a digital version of METL using these items. Using live data feeds from METL, there is a digital twin of the 220+ heater zones used to keep METL’s sodium at the molten level.

In fact, the team referenced an 800-gallon sodium tank with accompanying valves and pipes, all clearly labeled. The tank appears at its true size, oriented correctly, and fitted properly within the actual space. In virtual form, a technician could actually see it covered in insulation and castings.

Each part links to its own unique QR Code, containing its product serial number. METL was confident in its system so the team brought in a novice technician. They tasked them to find and repair a single valve or pipe on the tank. The technician found it quickly and repaired it with fewer mistakes.

Future workers from numerous backgrounds will likely do well with this new program. Most of what is used in this area people will already know because of our introduction to it. Not in school, but in our daily lives. The younger generation is already comfortable with the digital path to data.

Does this mean this move by one government facility will change the landscape of everything as we know it? Who knows? It is possible that this concept could catch steam and become a big part of the workforce. Even lead to innovation and new opportunities from it.

Changing The Game…Literally

One vision narrative within the nuclear industry, academia, & government…the idea of modernizing a nuclear workforce with digital twins, AI, and integrated big data could actually result in reduced operating costs, improved safety, and much fewer human errors & consequential events. Plus, a greater employee attraction, satisfaction, and retention.

Interestingly, this might also help the gaming industry too. Real-life industrial applications and experiments could offer a lot of new opportunities for the gaming/entertainment industry. The use of this tech might lead to advanced manufacturing and facility operations/maintenance.

Argonne’s Director of the Materials Manufacturing Innovation Center, Chris Heckle, stated:

“From an industry perspective, when a person on-site can use an iPad to run a complex diagnostic and then have a service technician from afar advise on how to fix an issue, it saves money on travel and increases uptime.”

More trial runs are needed before METL pushes this even harder, but it’s already in use. There are already even ideas for what the gaming industry can do coming out of the facility. Such as the idea of using infrared cameras.

More adoption of extended reality tools could even bridge the gap between the nuclear industry’s historical and future success. Kultgen claimed:

“We have to ask not only how we can get a reactor built on budget and on deadline, but we need to attract and retain a knowledgeable workforce capable of operating and maintaining it. These huge investments take time, so how do we keep trained, skilled people engaged in and committed to the nuclear industry?”

Resources:

https://www.anl.gov/article/argonne-tests-gaming-technology-to-train-nuclear-workforce